- Cooling Tower Design Calculation Software Pdf

- Cooling Tower Design Calculation Software

- Cooling Tower Design Calculation Software Online

DesJardins

COOLING TOWER SOFTWARE AND CONSULTINGSERVICES

Over62 years of service to the evaporative cooling industry

PSYCHROMETRICPROBLEM SOLVING SOFTWARE

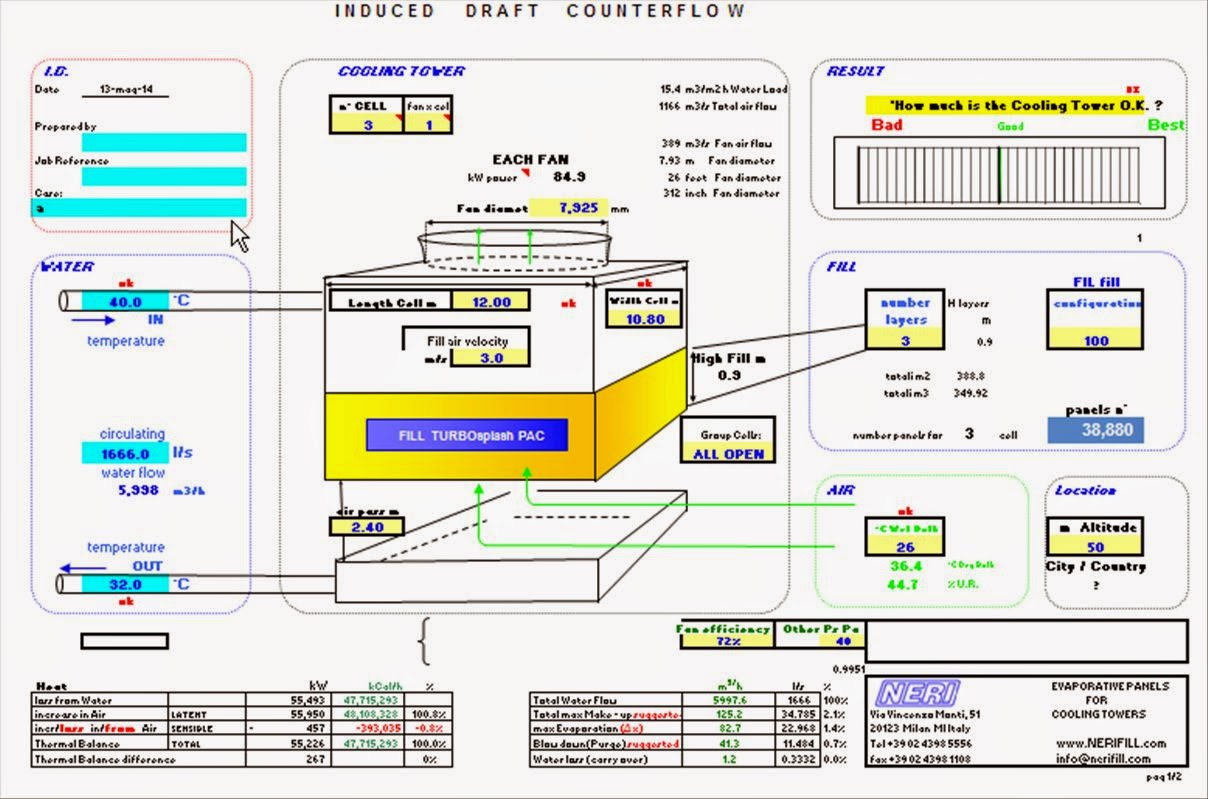

- Cooling Tower Calculations software program is a powerful, user friendly, software program for the analysis of induced, mechanical-draft, counterflow cooling towers. The software program can be used for the analysis of existing towers or for the preparation of specifications for new towers.

- Try our Neri calculator tool for free. When you sign up, we offer you a 1-day free trial of 50 calculations. This useful and easy program let you quickly and securely perform calculations for the design of a new cooling tower project, upgrade the performance of an existing counter-flow tower and verify its efficiency and working conditions.

Cooling Tower Basic Calculations February 28, 2017 0 Comments The recirculation rate and the temperature drop across the cooling tower are the two pieces of data needed to calculate the amount of water lost from the open recirculating cooling system (due to evaporation).

COOLINGTOWER THEORY

EVAPORATIVE AIR PRE-COOLERSFOR AIR COOLED HEAT EXCHANGERS

TECHNICAL PAPERS BY DESJARDINS

COOLING TOWER THEORY

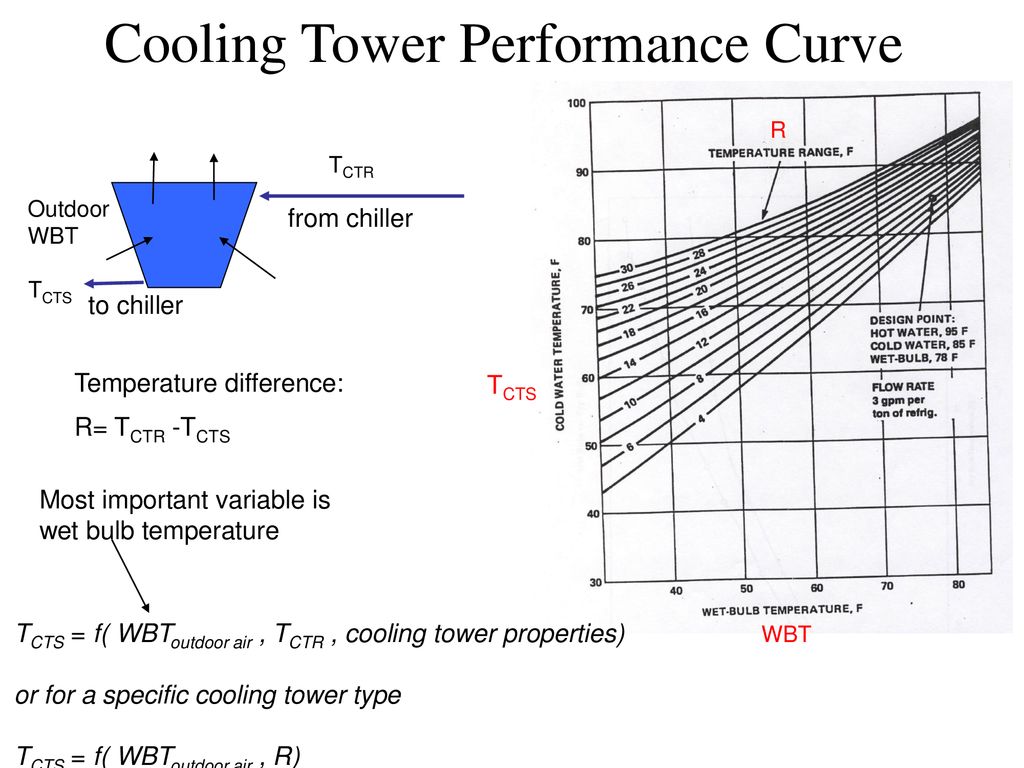

The crossflow and counterflow thermal design programs arebased on the Cooling Tower Theory presented in CTI technical paper TP92-01. Use of standard CTI Merkel Theory can result in designs that under-perform,sometimes by as much as 15% to 20%. For many years it was known that thesimplified Merkel Theory often needed a hot water correction factor or thatthere were errors or too many simplifications in the theory. Thesedeficiencies have been confirmed by many official CTI field tests. Hallet,Pritchard, Lefevre, Bentley and other members of the CTI Non-Merkel Theory committee presented many theories. It was concluded that any theory that hasresults with excessive scattering of the test data points justifies a bettertheory. Initial analysis using standard CTI type Merkel Theory programs oftest data collected by EPRI at their test facility showed considerable scatterof the test points. Actually it was found the data was very accurate, and itwas the cooling tower theory that needed to be corrected. It was necessary to useshigher quality calculus integration and psychrometric equations, a realizationthat the enthalpy of the water film around a drop of water is not the same asthe enthalpy of the bulk water temperature in the middle of the water drop sothe enthalpy driving force may be less than originally expected, the LewisNumber is less than 1.0, evaporation needs be considered, and it might benecessary to provide adjustment factors based on air velocity for some fills. Clients have reported our offset theory corrects for these problems, andapparently when compared to other programs such as the MRL program even withits Merkel Correction Factor may result in better performance prediction. Asone old time cooling tower executive said: The object is to make the pointsline up, not necessarily in a straight line on log-log graph paper, but atleast on a smooth curve even when considering different air rates or nozzlepressure. If the theory is good when you put the test data in, and the pointsline up, then you should be able to get reliable results when you take the dataout and use it to design your tower. Our programs also include quality fan andpressure drop data that may be different than some data presented by optimisticfan manufacturers that do not use practical tip clearance and fan cylinderdesign.

EXAMPLESOF DESIGN THERMAL RATING PROGRAMS:

CALCULATE MECHANICAL DRAFT TOWER PERFORMANCE

OBTAIN ACCURATE PREDICTIONS

ANALYZE YOUR BIDS

EASILY INVESTIGATE ALTERNATE OPPORTUNITIES

Cooling Tower Design Calculation Software Pdf

Use it to quickly andaccurately step through your process, changing the pressure as you go, asactually happens in the real world, combine air streams, add or remove heat,and quickly solve evaporation or condensation problems.

Condensation andevaporative heating or cooling calculations are made easy. The amount of wateradded or condensed is calculated. Icom ic-f1000 programming software download. Flow entry can be in CFM or pounds of dry airor pounds of mix. The psychrometric program calculates the properties of moistair at any elevation to 20,000 feet and for pressures to 35 psia.

The Mol Weight andSpecific Heat can be revised to allow calculations of properties of other moistgases (such as flue gases). Hot gas scrubbing calculations are made easy.

- The program uses four different pressure input modes: altitude, psia, inches mercury or inches water gage absolute.

- Nine different property input modes are possible: dry bulb - wet bulb; dry bulb - relative humidity; wet bulb - humidity ratio; enthalpy - humidity ratio; dry bulb - humidity ratio; dry bulb - enthalpy; wet bulb - relative humidity; enthalpy - relative humidity; and humidity ratio - relative humidity.

- Given any two of the above properties and a pressure, the other properties are calculated along with three different specific volume options, the dew point temperature, three vapor pressure options, and the density of the mix.

- Toggle your input or results between Metric and IP units.

Cooling Tower Design Calculation Software

home

COOLINGTOWER CONSULTING:

Many companies which no longer havethe luxury of having an experienced cooling tower engineer on their staff nowuse our services.

Custom developed thermalrating programs for both counter flow and cross flow towers are used to providequick, accurate tower performance predictions.

Although we are

SERVICES WE HAVEPROVIDED FOR OUR CLIENTS HAVE INCLUDED:

- Bid analysis and thermal performance evaluations

- Specification preparation

- Inspections

- Review for thermal upgrade

- Economic comparisons and evaluations

- Practical review of project needs

- Confidential preliminary tower sizing and budget pricing

- Review material requirements

- Psychrometric, water conservation, and plume abatement problem analysis and design

- Evaporative cooling process studies

- Designs of cooling tower and evaporative cooling sections

- Dry and wet tower economic analysis

- Owner's Representative to monitor thermal performance test

- Thermal performance tests

- Expert Witness

- Technical assistance for attorneys and management

CONSULTING SERVICESAND CONCEPTUAL DESIGN were provided to a geothermal power producer for the1,556 foot long, 30 fan air cooled heat exchanger shown below. The alternativeconventional designs would have had as many as 220 smaller diameter fans to maintainor an A-frame forced draft design that would have been much more subject to airdischarge recirculation. CTI technical paper TP16-27 fully describes thisunique design.

SOME EXAMPLES OF THOSE WHO HAVE BENEFITEDFROM OUR SERVICES

- A major power producer now saves over $300,000 per year because tower performance was up-graded at the time of replacement.

- A repair contractor's fill replacement recommendation was changed to get greater performance for less cost.

- Bid analysis of many proposals revealed possible performance problems, and material and design deficiencies were discovered.

- A specification was developed to encapsulate a failing galvanized steel tower in fire retardant fiberglass, saving the client over $250,000.

- A thermal performance rating program was developed for a major cooling tower repair firm.

- Many specifications have been prepared for refinery and power plant projects.

- Tower repair inspections and construction inspection services have been provided for many projects including specification preparation and thermal performance improvement review.

- Evaporative air pre-coolers have been designed and built for air cooled heat exchangers and turbine air inlet cooling.

- Several turbine inlet air chilling studies have been made, including formal preparation of turnkey bids.

- Plume abatement studies and designs have been provided for several environmentally sensitive projects.

- A complete line of packaged cooling towers was designed for a foreign company including drawings for every part, computerized thermal rating system, inspection of prototype, operation manuals and installation instructions.

- Thermal tests complete with analysis for energy rebates have been provided for high-rise office buildings.

- Expert witness data has been provided for attorneys.

- Complete design and operational analysis of plume abated cooling towers located in noise and vibration sensitive areas.

Nero burnlite 10.0.10600 serial number. The design of the tower shown above and below includedthe following:

Cooling Tower Design Calculation Software Online

Download map bussid pc.

INDUSTRIALQUALITY FOR AIR COOLED HEAT EXCHANGERS,

Evaporative airpre-cooling can significantly decrease your initial capital costs, operatingcosts, and in some cases allow you to do what otherwise would be impossible.Standard air cooled heat exchangers operate on the dry bulb temperature as thelowest temperature sink for disposal of heat. By using evaporative sections inadvance of the air cooled exchanger it is possible to reduce the dry bulb tonear the wet bulb temperature by evaporating moisture into the air stream, thuseither reducing the amount of surface required, reducing the operatingtemperature, or increasing the number of hours you can operate at the designdry bulb temperature. Often the use of an air cooled heat exchanger withevaporative air pre-cooling sections can be used where a cooling tower thatrequires much more year-around water supply would preclude the building of aplant.

We have over 62 yearsof experience with evaporative cooling equipment. Our computerized sizingsystem allows accurate design at any elevation and inlet design condition. Ourattention to details meets the requirements of the media manufacturer forelimination of leaks, drips, scaling splash-out and proper distribution.Additionally, the distribution of each system design is operated in the factorytest unit prior to fabrication of the final product to assure you of a properlyfunctioning field installation.

DESIGN CONSIDERATIONS

As a standard coolingmedia we use Munters Corporation Glasdek material. Performance and pressuredrop are typically defined as shown in the attached 'Efficiency' and'Pressure Drop' graphs with further adjustments made for highaltitude applications. For preliminary design investigations please considerthat most applications will be economically viable with 6' and 8'thick media operating at about 1.5 gpm per square foot of media plan area and aface velocity of 650 fpm maximum. The maximum net height of each media sectiongenerally cannot be more than 10 feet. Applications requiring greater heightwill require split distribution systems. Standard structures are all welded#304 stainless steel. If you are investigating the use of evaporative airpre-cooling sections please contact us for assistance. We would be pleased toprovide you with information on reducing fan power requirements, make-up andblow-down requirements, and where to obtain proper information on watertreating and general layout requirements.

Comments are closed.